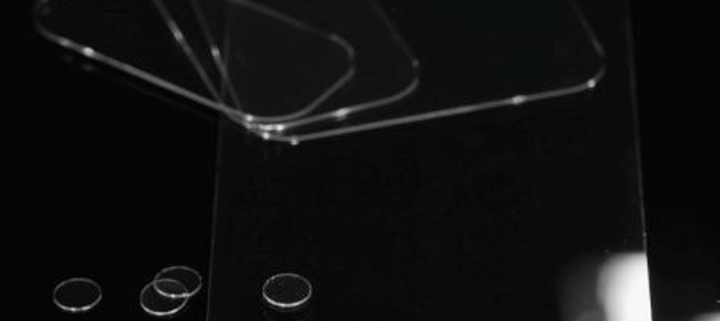

The hand-held fiber laser marking machine can process corporate logos, food packaging date text, mobile phone shell patterns, anti-counterfeiting codes, barcodes and other information. Hand-held processing is also convenient for marking some large mechanical equipment or parts. Its laser marking The processing technology is very practical.

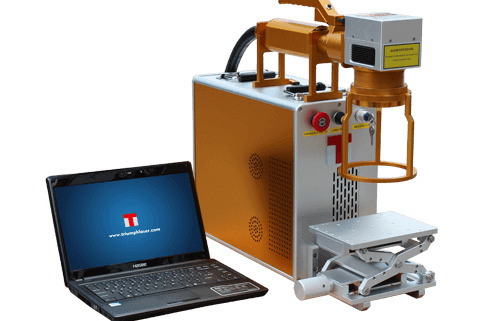

Customers can save a lot of cost when using a hand-held laser marking machine for marking processing, and obtain greater benefits with a small cost. Compared with various large-scale laser marking machines, portable laser marking machines can carry on printing. They are portable and easy to operate. They are also called handheld because of their compact and convenient operation mode. Type laser marking machine.

The handheld laser marking machine is maintenance-free. The maintenance of the machine is one of the methods to make the machine work better, and the maintenance-free feature saves customers a lot of unnecessary trouble, saves time, and indirectly improves work efficiency. The marking machine has clear and fine marking characters and low energy consumption. The portable laser marking machine acts on the material, and the processed product has a vivid and clear image, which is easily accepted by the market.

Its main feature is that it is compact and convenient. It can be hand-held for operation, and laser marking large mechanical parts in any direction; it solves the problem of laser marking of large parts. It can be widely used in large-scale equipment manufacturing industries such as: railroad tracks, wheel tyres, train manufacturing, aircraft manufacturing, hydroelectric generators, wind generators, steam turbine motors, engines, large bearings, shipbuilding, and large molds. In short, the handheld laser marking machine can flexibly process parts around.

The portable handheld laser marking machine adopts fiber laser, which is characterized by: photoelectric conversion efficiency up to 30%, good beam quality, high efficiency, long life (average life of 100,000 hours), maintenance-free, small size, no consumables, air-cooled, Low energy consumption. Operating costs are extremely low.

With the rapid development of the manufacturing industry, the laser marking machine industry has also been driven. Laser marking technology is well-loved in all walks of life. With the continuous expansion of market demand, the functional requirements of laser marking machines in various industries are also increasing and higher.

It is characterized by its compact size, which can be put into the trunk of a car for easy handling, and it can work even in a small workshop. With the gradual popularization of laser application technology and the development and growth of related manufacturing industries, the scope of application of handheld laser marking machines has increased, and traditional production and processing industries have become more and more available.

If you need to engrave the logo of your product, use a Triumph laser marking machine.

If you want to learn more about laser marking machine, please don’t hesitate to contact with me.

Email:sales1@triumphlaser.com