Laser cutting technology has become most important part of the manufacturing process and hence it accounts for 70% of laser application industry. These high precision Laser cutting Machines have successfully made their mark on in market with their great set of features and totally ruled out the traditional cutting technologies. There is a multitude of benefits these Laser cutting machines provides but I will try to list few of them for you below:

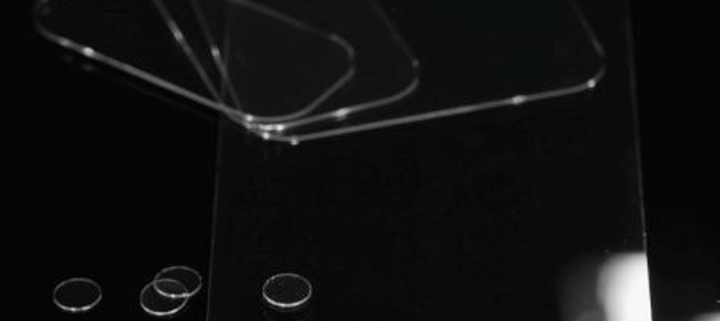

Works with wide range of materials and thickness: Laser cutting possesses the ability to cut effortlessly through a wide spectrum of materials like stainless steel, carbon and mild steel, aluminum and aluminum alloys, copper, brass, bronze, titanium, timber, acrylic, rubber and fabric. It can cut through thicknesses of 0.5mm to 25mm

Precision repeatability: High precision Laser Cutting Machines provides easy and accurate repeatability to the model maker which is highly desirable in case of mass production.

Improved Edge quality: These machines provide very clean edges as compared to conventional methods. Due to non-contact nature of this process, no wearing is caused by the tool, no mechanical force is directly imparted on the part which prevents any kind of material distortion or workpiece contamination. Heat affected zone(HAZ) is also reduced.

Easy Maintenance: Industrial Laser Cutting Machine requires very inexpensive replacement parts like nozzles and lenses which make them easy and low maintenance systems.

Lower lead time: A single Industrial laser cutting machine can cut materials of almost any size, type and shape hence it provides very less lead time.It can generate 3D shapes and complex designs on any sort of material which is somewhat difficult for traditional cutting machines. A Laser Cutting Machine consumes less energy while cutting sheet metal.

Accurate results: A Laser Cutting Machine is totally computer programmable hence generate accurate results and offers a great amount of control to the user.

Fast: High precision Laser Cutting Machines are way to faster as compared to conventional cutting machines.

The business of Industrial Laser Cutting Machines is booming day after day. If you are also thinking about purchasing one for your manufacturing unit then Triumph Laser is a place for you. Triumph Laser provides a variety of laser cutting machines like Oxy Fuel, Nitro Fuel, Sublimation, Scanner, Kiss and Robotic cutting. A customer-centric approach of Triumph Laser compels them to take a step further and provide customized laser machines perfectly suitable for your application.

If you want to learn more about laser cutting machine, please don’t hesitate to contact with me.

Email:selina@triumphlaser.com